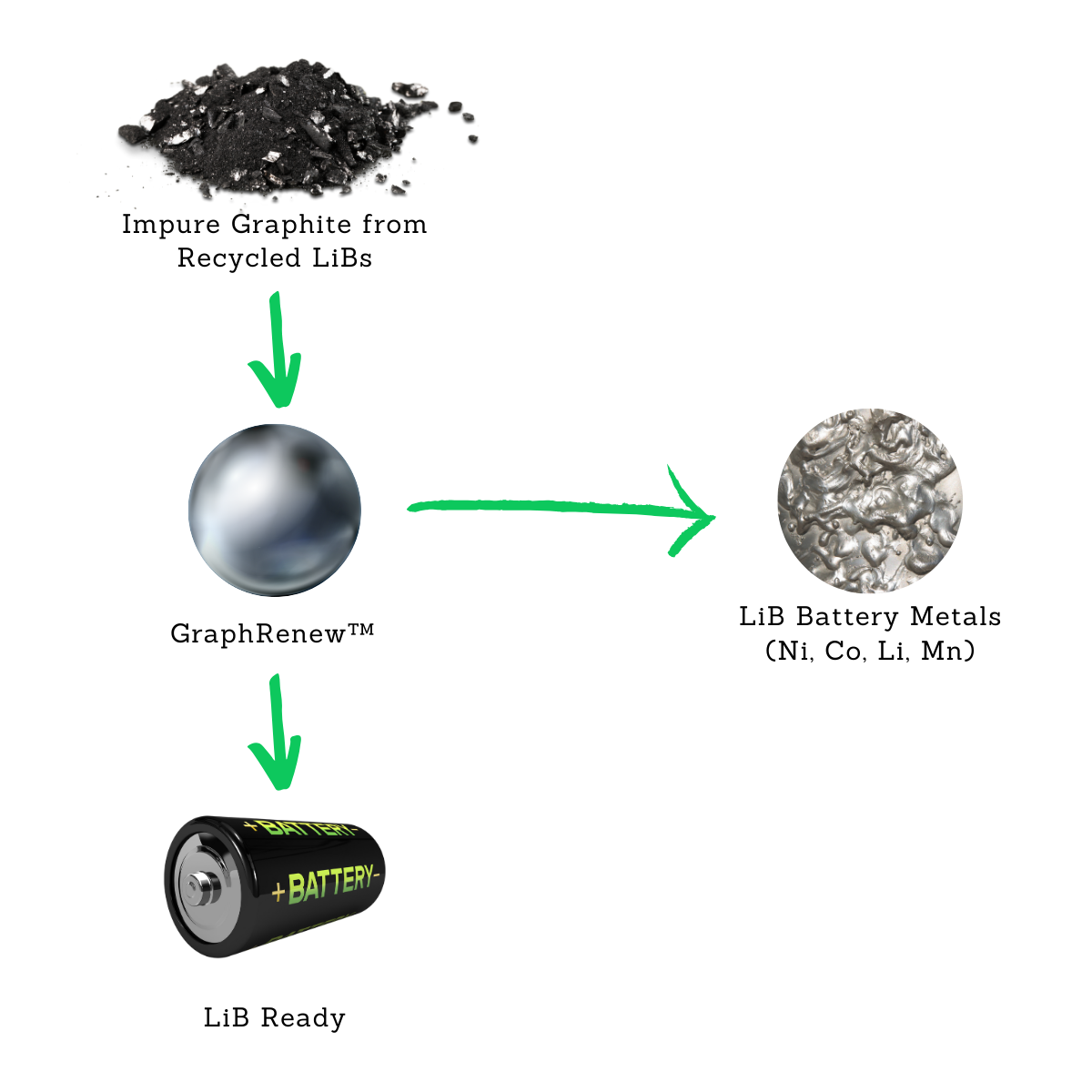

GraphRenew™

Enabling LiB recyclers to transform spent graphite into LiB-grade graphite

Lithium Ion Battery

Recycling

The LiB recycling market is forecast to experience significant growth commensurate with the growth in uptake of LiBs in EVs and consumer products. A key factor in this growth is government initiatives and regulations, especially in North America and Europe, to promote a circular economy for LiBs.

Given the demand for recycled battery material, it is not surprising that there are multiple companies developing hydrometallurgical processes for recycling LiBs. The focus of these companies has been on the recovery of the Cathode Active Materials (CAM), which includes Lithium, Nickel, Cobalt and Manganese.

GGT is actively collaborating with multiple LiB battery recyclers and is looking to collaborate with battery cell manufacturers who currently don’t have a solution for upgrading their waste or off-spec anode (graphite) material. Currently, the only options are sending it to landfill or to a smelter as a fuel. These options do not promote a circular economy and do not help to address the massive supply gap for this much needed critical mineral.

Advantages of

GraphRenew™

The competitive advantages of GraphRenew™ are due to inherent technical features of the underlying GraphPure™ technology.

Recovery Process

GraphRenew™ can effectively remove “spent” graphite with minor amounts of cathode metals and purify the graphite to reintroduce it into the battery supply chain. Off-spec anode material can also benefit from GraphRenew™.

Reagent Recycling

The incorporation of efficient reagent recycling lowers processing costs and minimizes the environmental footprint.

Scalable

This is a scalable process that can be sized and expanded to coincide feedstock availability, especially as the nascent LiB recycling industry grows.

Enabling Technology

Graphite Recovery with GraphRenew™

When recycling LiBs, there are two general methods that can be used: pyrometallurgy and hydrometallurgy. Presently, the main method used to recycle LiBs is pyrometallurgy in which LiBs are fed into existing high-temperature smelting processes.

Although this allows some of the valuable cathode metals in the LiB – such as Nickel, Cobalt, and Copper – to be recovered, other metals – such as Lithium – are lost. In addition to this, the valuable graphite is simply burnt as fuel.

Recently, several companies are developing hydrometallurgical processes for recycling LiBs which are able to recover more of the valuable cathode metals including Lithium. The majority of these hydrometallurgical LiB recyclers produce waste (spent) anode graphite and need to find a solution to promote a fully circular economy. To date, our company has received ten letters of support from LiB recyclers willing to collaborate towards the rapid commercialization of GraphRenew™.

The Status of

GraphRenew™

GraphRenew™ has been proven at the bench and pilot scale to recover graphite from spent LiBs that meet the purity specification of >99.95%. Moreover, preliminary commercial flowsheet and technoeconomic analysis (TEA) has been completed.

Looking to invest in a greener future?

Ready to have your material tested?