GraphPure™

Cost Effective + Environmentally Friendly + Sustainable = Game Changing

GraphPure™

Technology Overview

Unique Purification Process

A holistic approach that considers the processing cost, environmental impact and operational flexibility

Sequence Flexibility

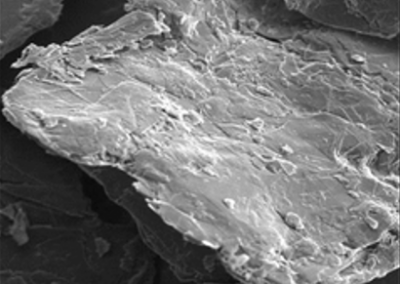

GraphPure™ can treat graphite independent of particle size and shape, which provides significant opportunity to optimize the sequencing of unit operations.

Operating Conditions

Operating conditions are tailored for each NFG source based on specific impurity make-up

Reagent Regeneration

The processing reagents are cost-effectively recycled in-situ

Renewable Energy

No fossil fuels required and zero carbon footprint possible

Battery-Grade Graphite Confirmed

Demonstrated (>99.95% purity) at pilot scale on multiple graphite types. Anode performance on par with reference in LFP and NMC batteries.

At A Glance

Our Integrated Technology Package

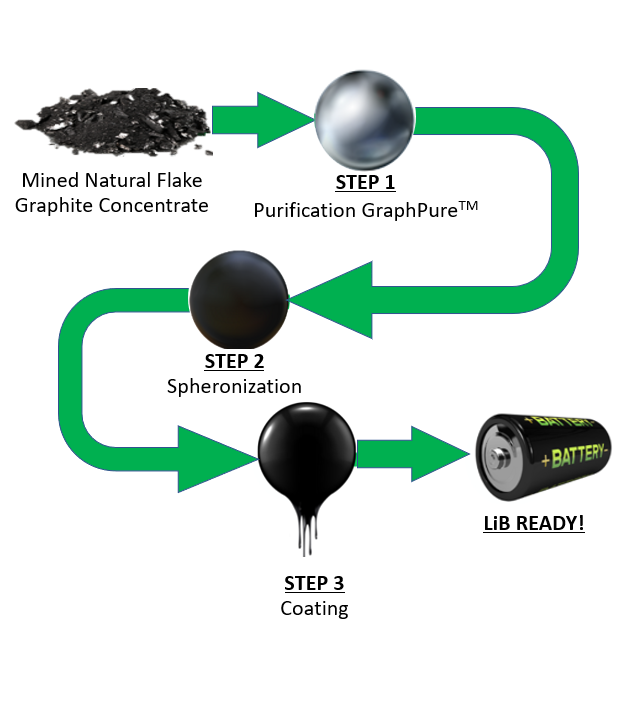

At the heart of our Integrated Technology Package is the GraphPure™ purification technology. Our technology removes the key technical bottleneck inhibiting growth of the non-Chinese LiB-grade NFG graphite market.

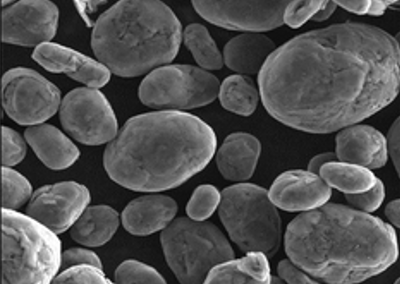

However, to meet LiB-grade graphite specification, the NFG must also be appropriately sized and shaped (termed micronized and spheronized) and coated with amorphous carbon.

GGT will supply the option for a fully Integrated Technology Package that will include micronization and spheronization equipment from existing suppliers and carbon coating from its partner Rain Carbon with GraphPure™.

The Integrated Technology Package will provide GGT’s clients with a complete solution to transform NFG into LiB-grade graphite.

(Steps 1 & 2 can be interchanged)

The Status Of

GraphPure™ Technology

We have successfully demonstrated GraphPure™ at the bench and pilot scale. The key technical and cost drivers have been identified and a techno-economic model developed, which is used to underpin the technology development and commercialization strategy.

%